With remarkable advancements in tool technology, it’s easy to feel like you’re falling behind the latest improvement. What’s more—differentiation inside common tool categories creates confusion. In generations past, when a craftsman needed a hammer, he went to the local hardware store and bought a hammer. Today that same craftsman might stand in front of the rows of hammers, deciding among a hickory handle, or fiberglass, or carbon fiber. Should he get the titanium head or steel and why? The incredible market mechanism that meets our needs also creates questions. What about the many types of drill bits? We can talk about the best drill bits, but let’s talk about the differences between black oxide, titanium, and cobalt drill bits.

Types of Drill Bits: Titanium (or TiN)

All of the different types of drill bits in these categories are based on High-Speed Steel (HSS), a designation you’ll see often when reading about bits. But the treatments those HSS bits receive to make them black oxide, titanium, or cobalt make marked changes in the performance, intended use, and longevity. Learning the differences helps you avoid wasting money and using the wrong bits for the wrong materials.

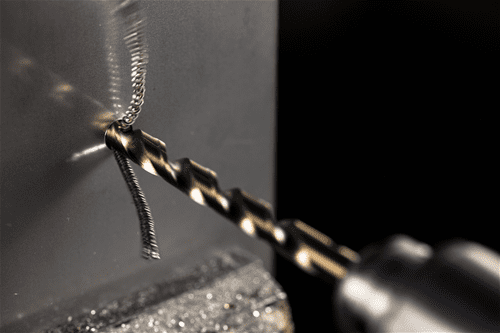

Titanium drill bits are HSS bits that have been coated with titanium nitride (TiN) using a process similar to electroplating. TiN is a ceramic material that increases the surface hardness of the bit and provides a thermal barrier by reducing friction. This results in increased production rates, corrosion resistance, and 3 to 6 times longer tool life. Titanium bits are suitable for drilling iron, steel, aluminum, magnesium, and wood.

Titanium bits are great for general purpose drilling in a production environment because they drill quickly. The TiN coating also helps chips flow thru the flutes which is helpful because some materials – like aluminum – adhere to bits more than others. However, once the tip is dulled, it won’t regain it’s cutting edge without being recoated in titanium nitride. It usually makes more sense to replace rather than recoat them. So even though they are harder than cobalt, their edge is only skin-deep.

Cobalt Drill Bits – Not a Coating

High-speed steel is alloyed with 5-8% cobalt to create cobalt drill bits. These are the best drill bits for metal due to their high resistance to the massive heat generated when drilling through highly abrasive and/or hard materials such as treated stainless steel, titanium, and cast iron. Unlike the TiN coating, cobalt is found throughout the entire material which makes it great for high production work.

Because of their durability and cost, most Pros don’t use cobalt drill bits for general purpose use. The extra hardness lets manufacturers make the flutes smaller as a percentage of the total thickness, increasing the strength of the bits. You can also sharpen them without losing cutting effectiveness. Cobalt bits cost more than TiN or Black Oxide bits, but many Pros find value in the toughness.

Manufacturers heat HSS bits to 950 degrees Fahrenheit, creating a black oxide finish that resists rust and corrosion. This reduces friction between bit and workpiece, thereby speeding up the drilling process. Bits made with a black oxide coating are suitable for work on steel, copper, aluminum, brass, oak, maple, MDF, pine, PVC, polycarbonate, acrylic, ABS, nylon, and composite materials.

Black oxide bits last up to 50% longer than standard HSS bits. They offer superior durability and speed. Many pros find they get years of use from them and consider black oxide bits the best general-purpose drill bits you can buy.

Wrapping It Up

We hope we’ve been able to help you understand the differences in black oxide, titanium, and cobalt drill bits. Have some Pro tips of your own on how you choose drill bits? Add them in the comments below or sound off on Facebook, Twitter, and Instagram.