Two New Lithium Battery Cell Designs are Changing the Cordless Power Tool Industry

When lithium-ion power tool batteries showed up, they were a big improvement over Ni-Cad and NiMH chemistries. Two new designs are emerging, but in the pouch cell vs tabless cell batteries conversation, what exactly are we talking about? And does it really matter?

Pouch Cell vs Tabless Cylindrical Cell Batteries

What is a Pouch Cell Battery?

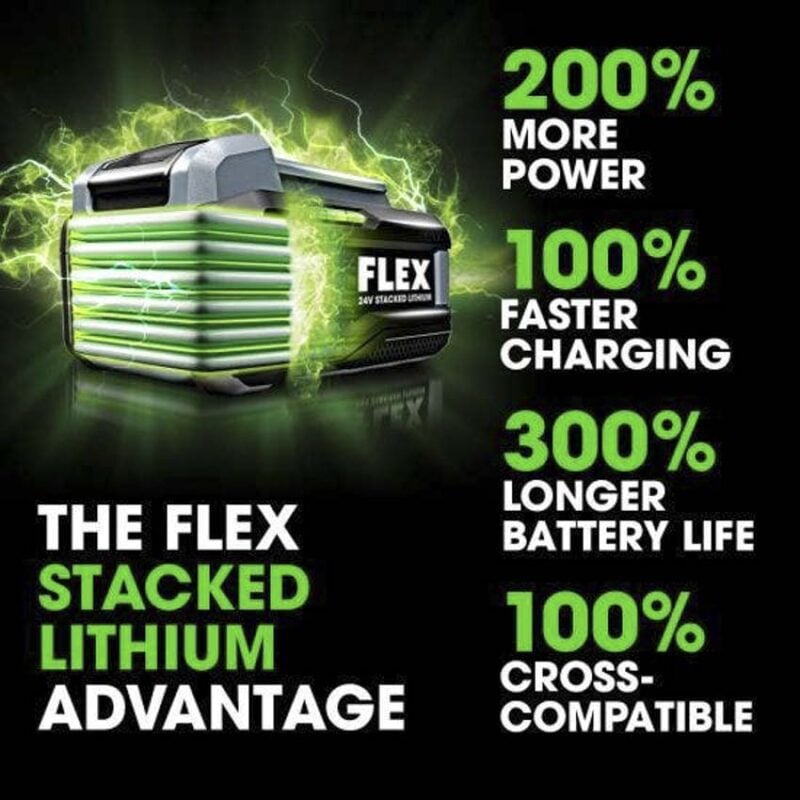

Pouch cells have been in the power tool industry longer than tabless cylindrical cells. We first saw it on Flex’s Stacked Lithium platform followed almost immediately by DeWalt’s PowerStack battery. In DeWalt’s defense, they announced PowerStack first, but we already knew about Flex’s even though we couldn’t talk about it until the launch date. Milwaukee’s M18 Forge is the latest to join the pouch cell offerings.

That all sounds exciting, but exactly what is a pouch cell battery?

Traditional lithium-ion cells are round while pouch cells are flat. They’re not paper-thin, but only a few millimeters thick, and still house all the internal materials required for relevant amp-hour capacity. The physical shape is what allows your cell phone to keep a thinner profile than it would if it used round cells.

When you make a power tool battery, you still need to use multiple cells just like you do with round cells. 18V/20V max batteries use 5-cell sets, 12V batteries use 3-cell sets, 36V batteries use 10-cell sets, and the list goes on. As Flex and DeWalt’s naming suggests, you stack these cells on top of one another when you build the pack.

What is a Tabless Cylindrical Cell Battery?

Milwaukee’s MX Fuel Forge batteries were the first to have a tabless design for round cells. Ryobi followed in early 2024 with a tabless design on its High Performance Edge packs.

Unlike pouch cells, a tabless design makes use of existing round cell shape. The “jelly roll” design is a nice way for the internal components to take up less room, but they typically have a soldered tab connection to the battery’s electronics. That tab is a significant source of electrical resistance and limits how much current you can safely run through it. The tabless connection removes that obstacle and opens up the electrical flow.

Pouch Cell vs Tabless Cell Batteries – Joining the (Lower) Resistance

The design of pouch cells is more than just another way to contain the cathode, anode, and separator in a different form factor. The tabless design is more than just a different way to connect round cells to the packs. The nature of both designs creates lower electrical resistance between the cell and the motor. That lower resistance results in more efficient energy transfer to the tool and the ability to safely push higher current through. Higher current produces more watts.

Breaking through all the geek speak, we end up with batteries that can deliver higher power to the tool, run cooler, and have significantly longer service life. It’s like getting off a crowded highway and onto an uncongested interstate. You’re running faster and the engine is happier since it’s out of the stop-and-go traffic.

There are two positive consequences. First, available tools get a noticeable boost in performance, even if you’re not using the latest and greatest. As you work closer to the limits of the tool, the more you’ll notice how the advanced battery design helps it push through.

The second positive is that manufacturers can develop more powerful tools on the same battery platform. For the manufacturers that have these innovative designs, we’re already seeing higher performing tools show up that are optimized for those batteries.

Pouch Cell vs Tabless Cell Batteries – Which One is Better?

Frankly, we don’t yet know for sure if pouch cell technology is better than tabless cell design. Consider that Milwaukee is deploying both in its Forge batteries. The big takeaway is that both designs offer impressive performance enhancements, and it will take time on construction sites to see if one is more durable or has longer life than the other. For now, I’m content to kick back and enjoy cordless performance that’s kicking the daylights out of my corded tools.