If you buy something through our links, ToolGuyd might earn an affiliate commission.

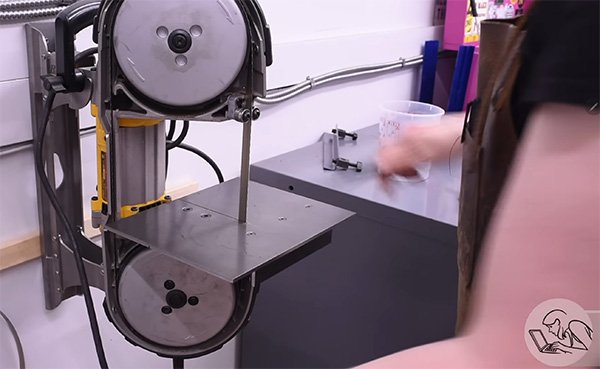

David wants to know who makes this prototype portable band saw wall mount that’s featured in a lot of Blondihack’s videos.

I don’t know, but I’ve been looking to learn the same!

She made the cutting table, but the mount is separate – it’s a prototype that’s been shrouded in secrecy.

There’s a new clue I didn’t see before – a stylized “R” on one of the mounting brackets, which David points out looks different – and perhaps somewhat logo-like – rather than being a “right” designation.

Who is Blondihacks? She’s a hobby machinist that produces wonderful educational and project videos.

Even if you aren’t interested in the educational aspect, Quinn’s project content is very entertaining.

Travis wrote: Check the picture in the description… AI strikes again! Nothing says “I love woodworking” like using a lathe shirtless.

I don’t know what to say here. Is this AI-generated, or just strange?

That’s one way to ensure long sleeves or drawstrings can’t get caught up in the machine.

Warren wrote: I saw on a Diablo 10″ 24-tooth ripping blade that it has high alternate top bevel teeth. Shouldn’t they be flat-top-grind?

Is this the one, model D1024X? I wouldn’t call that a high-ATB blade, but couldn’t easily find any other 24T rip blade.

Flat tooth angles are good for chiseling out material and leaving a flat and square edge. ATB are common for both ripping and crosscutting blades.

High ATB blades, with a higher tooth grind angle, are supposed to be better suited for reducing tearout, and according to the internet they can be better for cutting plywood and similar materials.

From what I read after refreshing my memory on saw blade tooth profiles, FTG rip blades are suited for faster rip cuts.

I recently ordered a Woodpeckers “ATBF” glue-line rip blade, which I’m thinking might have a combination of alternating and flat-top-ground teeth (similar to ATBR?), as well as an ATB combination blade. Neither arrived yet.

Woodcraft has a good article on saw blade selection (PDF).

A lot of rip saw blades are flat-top ground, but I’ve seen ATB blades as well. I think the main differences will be in cutting performance and surface finish.

With table saw blades, there are a lot of nuances, and I’m not yet experienced enough to be able to know from memory how different grind angles translates to different applications and surface finish expectations.

As bad as it might sound, I tend to go by brand designations. If a circular saw blade is sold for ripping applications, I tend to trust that, unless I have specific preferences otherwise.

I don’t think I’ve ever used a flat-ground blade. Most of my ripping tasks have been of thin plywood or softwood boards, and so I mainly used combination blades. I upgraded to a cabinet saw recently, and now I’m getting into ripping-dedicated blades for an upcoming project that will involve a lot of thicker hardwood.